Modern Air Mass Measurement and Temperature Correction

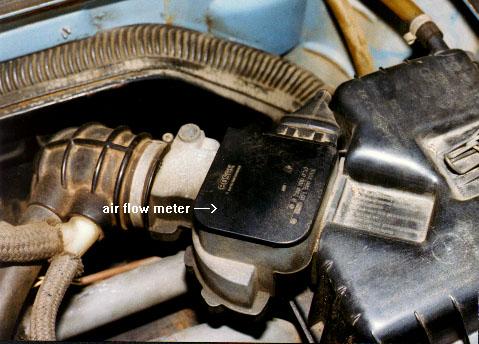

1. Volumetric Air Flow Meter-

A hinged door moves a potentiometer as air pushes it open. The Voltage in/Voltage out of the potentiometer is proportional to the volume of air flow. A temperature sensor is used to compensate for the air density, since mass= volume*density . Advantage- good accuracy in pulsing airflow, as the counterweight on the flapper door tends to average out fast changes in airflow. Disadvantage- The energy required to hold the door open is taken out of the air, creates a pressure drop, especially when sized too small.

2. Mass Air Flow Meter-

An electronically heated element is mounted in the intake air stream. (Bosch) A circuit is designed to keep the temperature difference between the element and the intake air constant. The current used is measured, and is proportional to the mass of air passing through the meter. No temperature/density correction is needed as this is one of the factors that determines the amount of warmth that the surrounding air absorbs from the heated element. (Bosch) Advantages- simple because air temp correction not needed, very low flow restriction. Disadvantages- heated element is easily contaminated, and very sensitive to pulsation and direction of the flowing air.

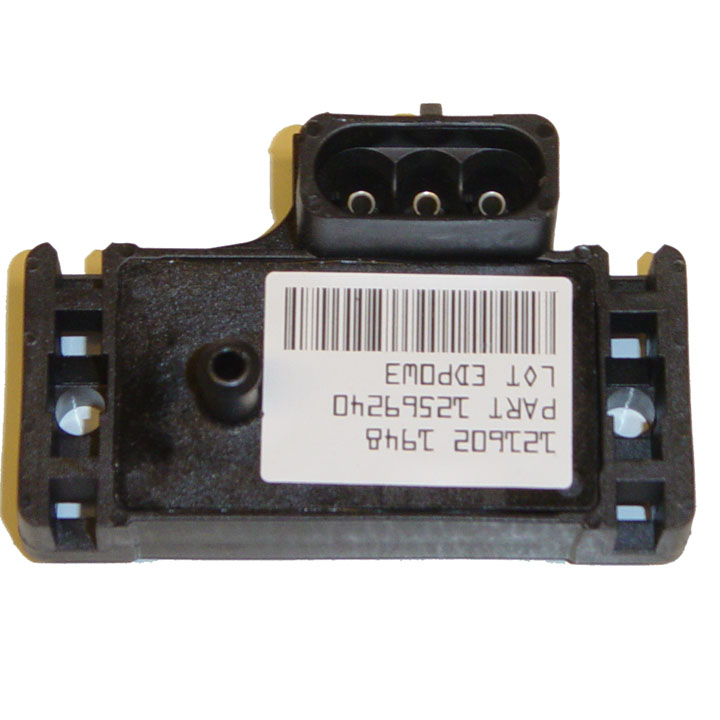

3. Speed Density Airflow Measurement-

One side of a bell shaped rubber diaphragm is connected to the intake manifold directly or through vacuum hose. The other side of the diaphragm is a reference volume of air at a known pressure. A series of piezo-resistive elements are arranged on the diaphragm; the electrical conductivity of these elements varies in response to changes in mechanical tension (caused by pressure difference across diaphragm). The voltage drop across the sensor is proportional to MAP.